Request Content

We would like to see how the following CO Production Order steps are processed within SAP.

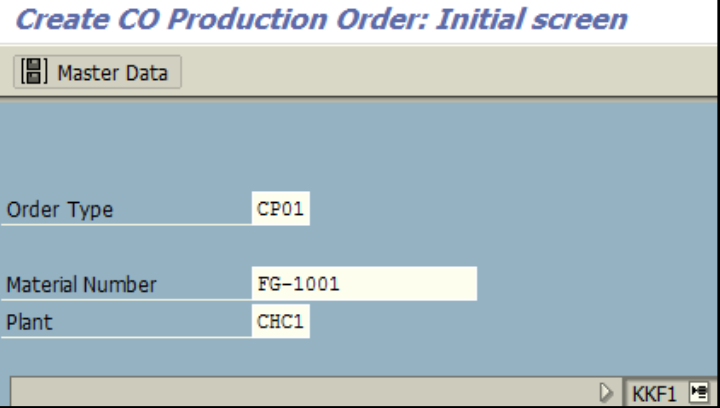

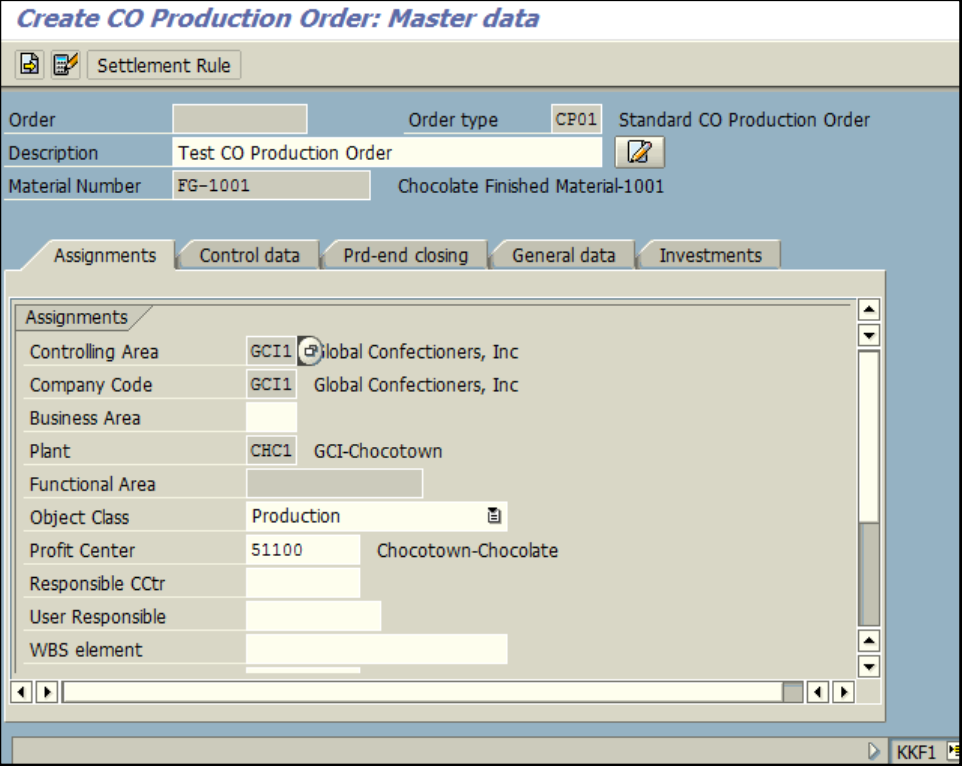

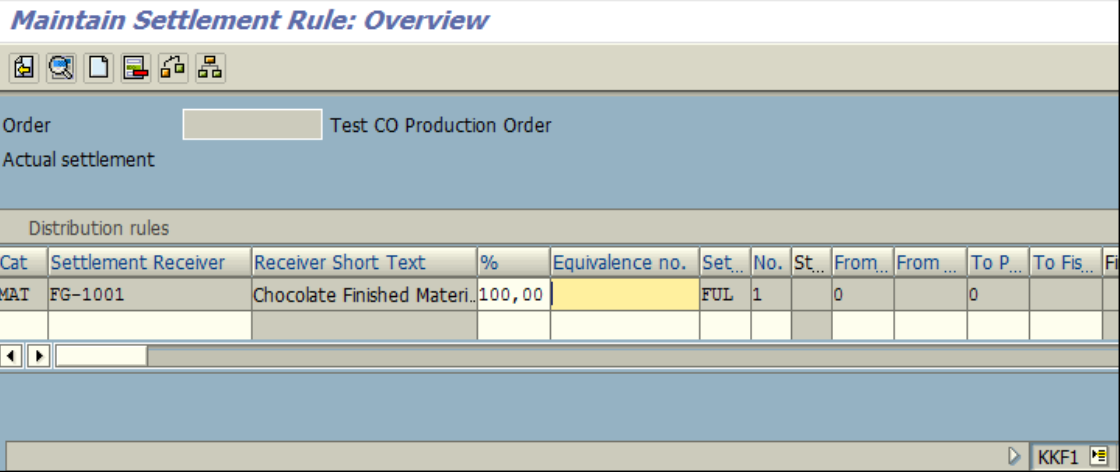

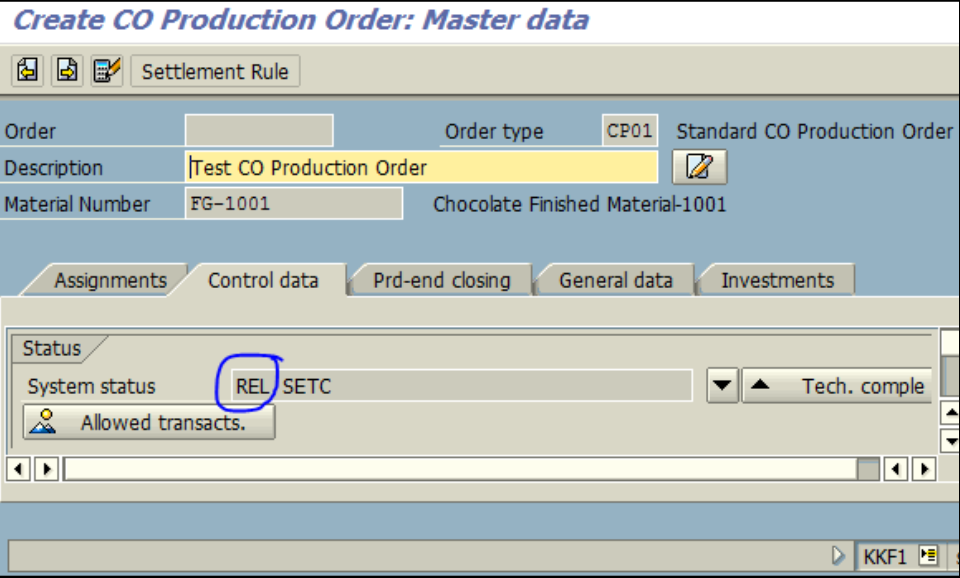

1. Creation and Release of a CO Production Order for a specific Material/Plant

Figure 1.1 KKF1 – Create CO Production Order: Initial screen – Order Type, Material and Plant are entered.

Figure 1.2 KKF1 – Create CO Production Order: Master data screen, Order text and Profit Center are entered.

Figure 1.3 KKF1 – Create CO Production Order: Settlement Rule screen – Settlement to Material is defaulted.

Figure 1.4 KKF1 – Create CO Production Order: Control data screen – Order is released automatically, based on setup in KOT2 for Order Type CP01.

Figure 1.5 KKF1 – Create CO Production Order: Order 702687 is created.

2. Updating the Plan Costs on the CO Production Order

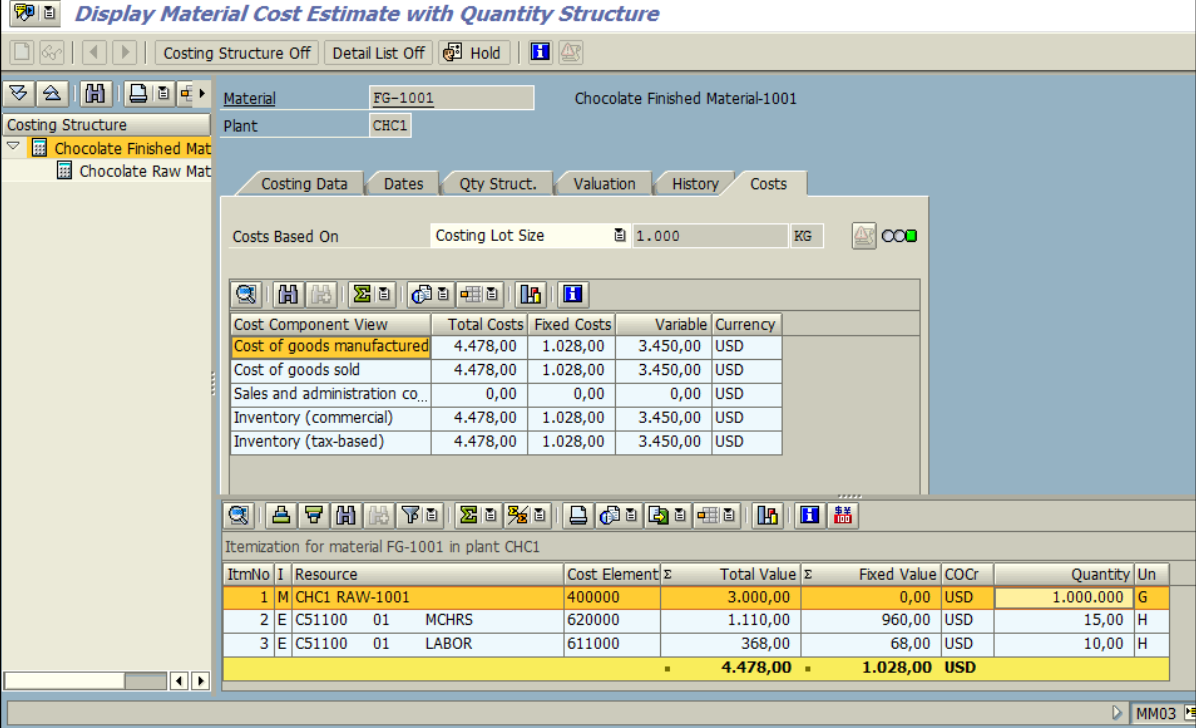

Figure 2.1 CK13N / MM03 – Standard cost estimate: Itemization view showing details of cost – Material and Activities.

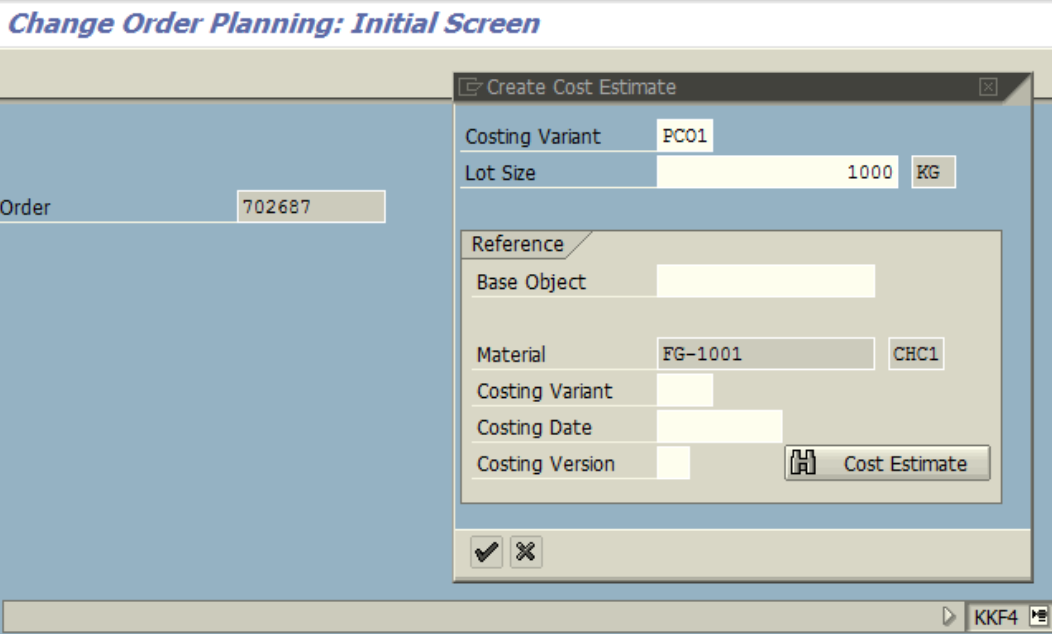

Figure 2.2 KKF4 – Order Planning screen, Costing Variant and Lot Size are entered for the given order 702687.

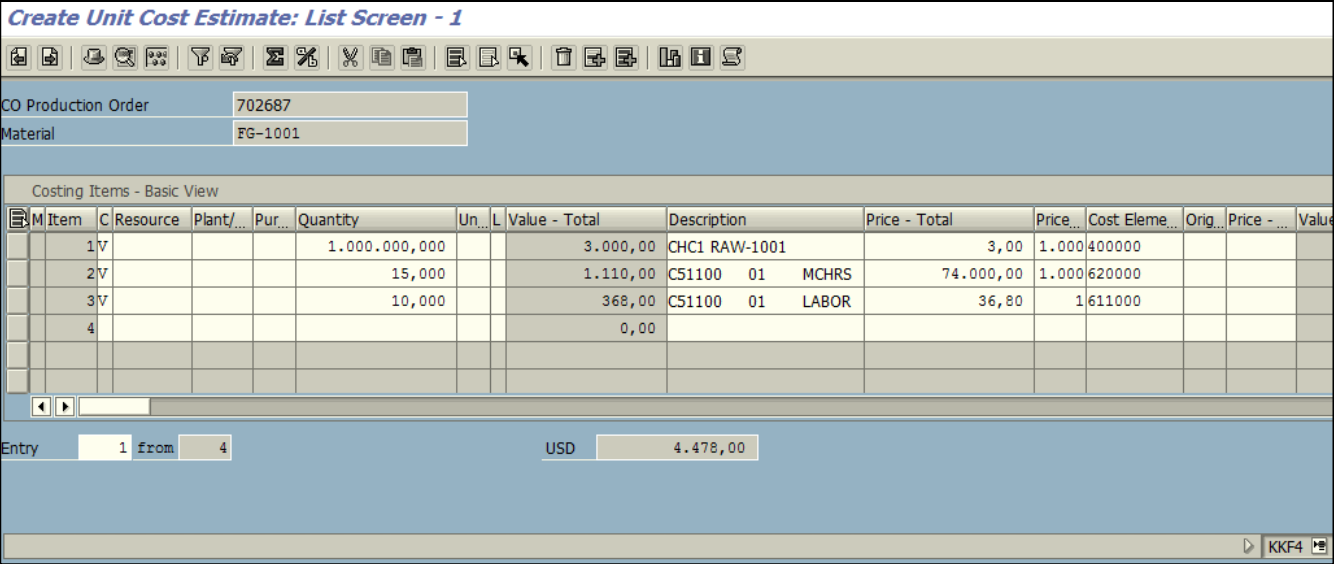

Figure 2.3 KKF4 – Order Planning screen, Unit cost estimate details are entered for the given order 702687 (CK13N data was replicated).

Figure 2.4 KKF3 – Order Cost Analysis screen, planned costs are seen on the order.

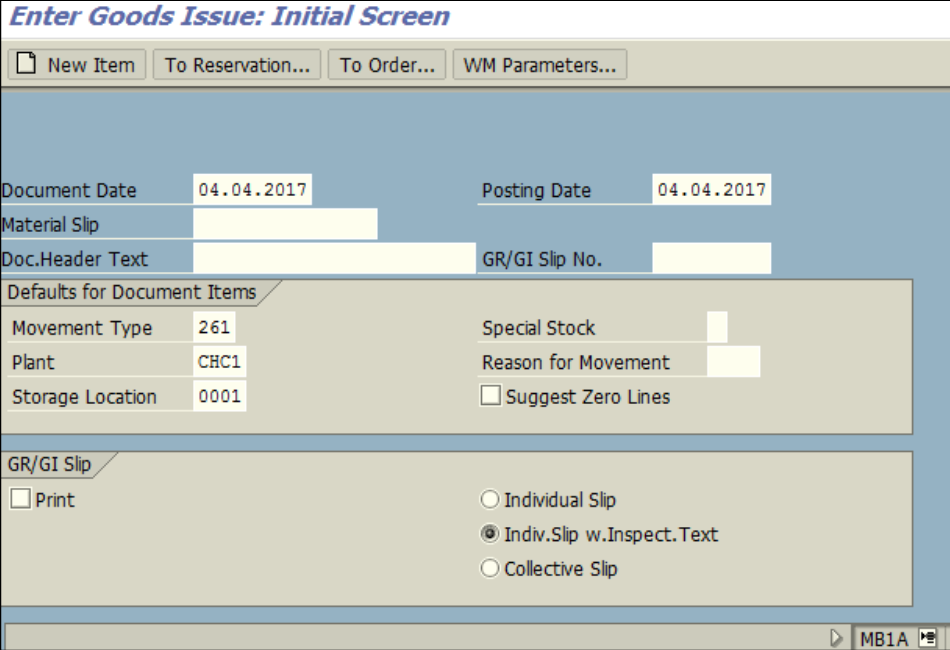

3. Issuing Raw Materials to the CO Production Order

Figure 3.1 MB1A – Goods Issue initial screen, Movement Type 261, Plant, storage location are entered.

Figure 3.2 MB1A – Goods Issue detail screen, Material number, quantity and batch are entered

Figure 3.3 MB1A – Goods Issue Material Document is posted

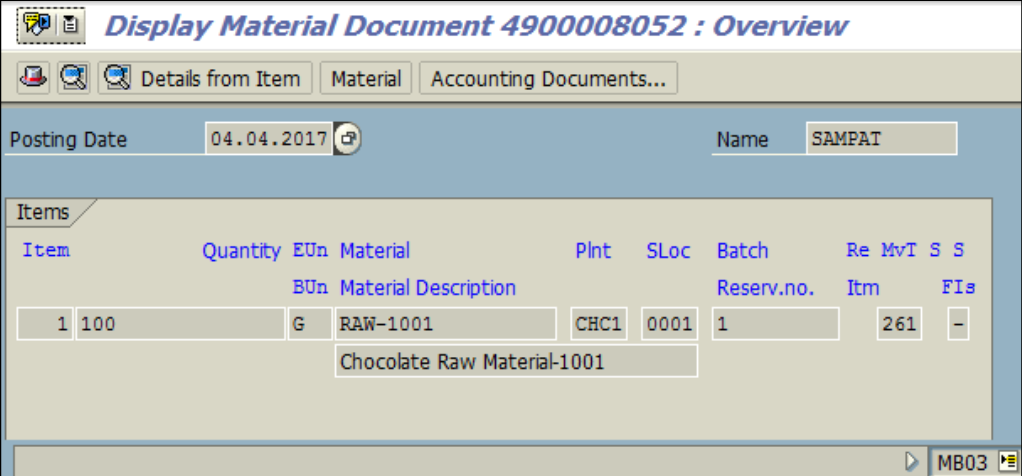

Figure 3.4 MB03 – Material Document for Goods Issue is displayed

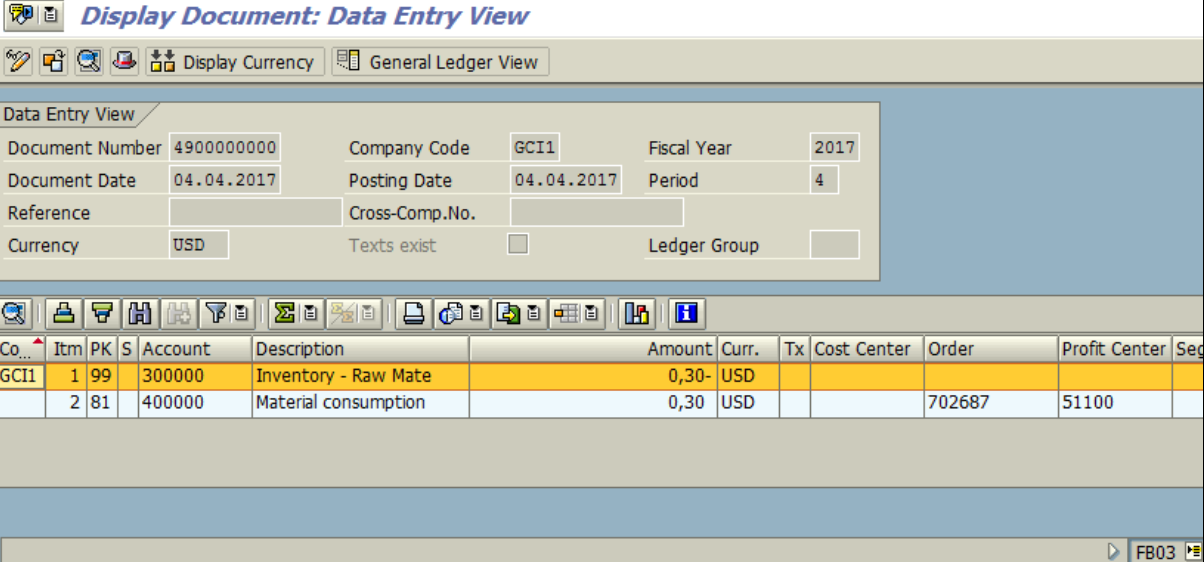

Figure 3.5 FB03 – Financial Accounting Document for Goods Issue is displayed.

4. Posting Activity Type Quantities on the CO Production Order

Figure 4.1 KB21N – Activity Allocation for Order – Cost Center, Activity Type, Order and Quantity are entered.

Figure 4.2 KB23N – Activity Allocation document for Order is displayed.

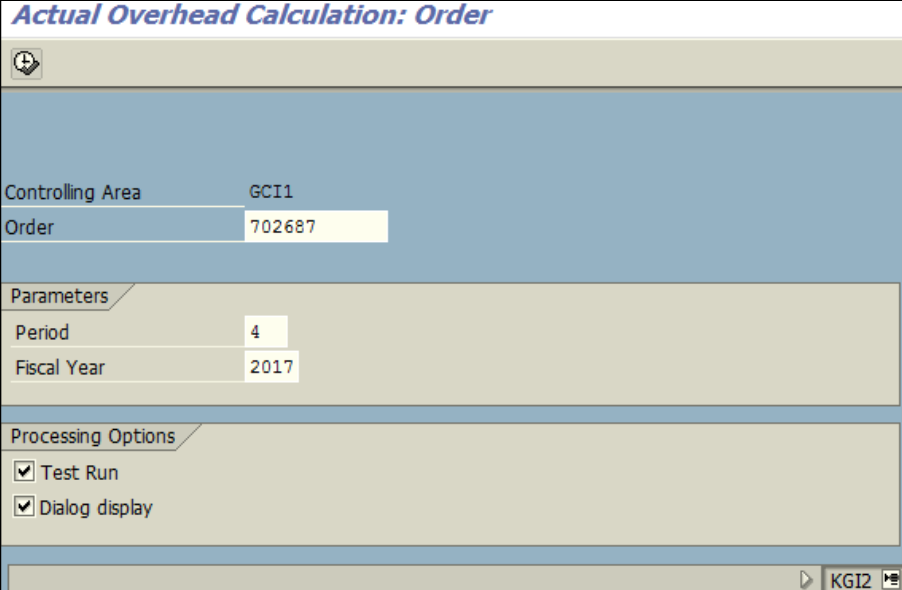

5. Calculating Overhead Costs on the CO Production Order

Figure 5.1 KGI2 – Overhead calculation: Order number, year and period are entered

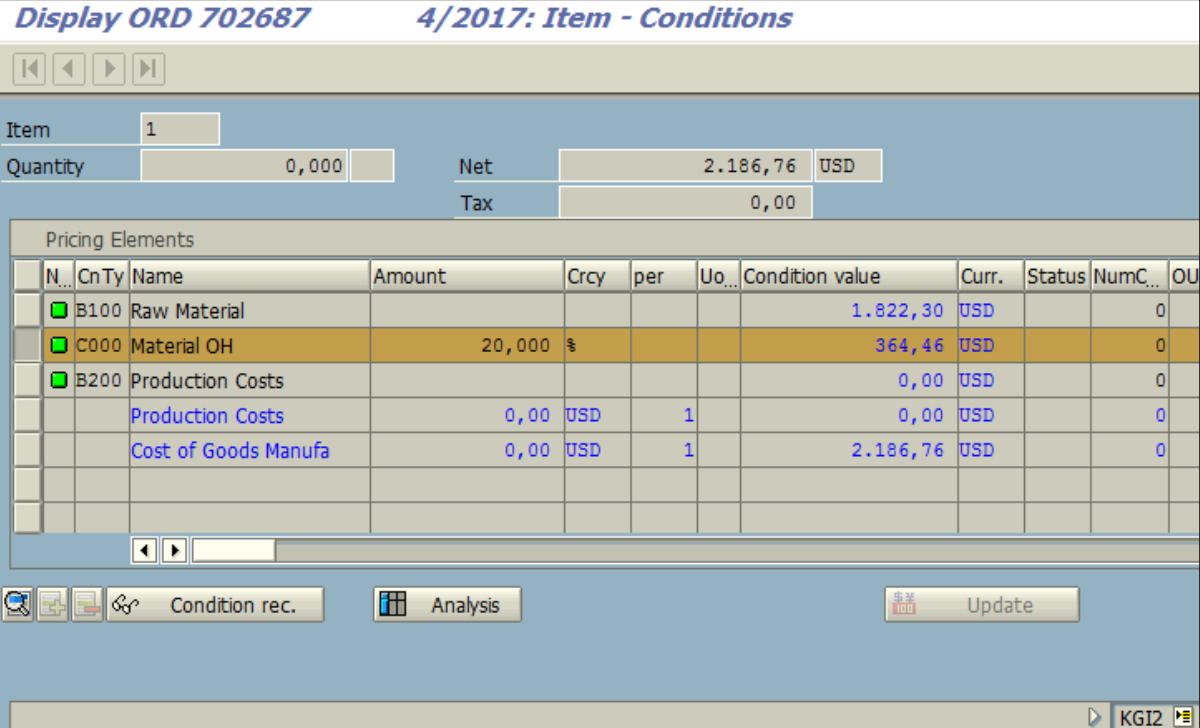

Figure 5.2 KGI2 – Overhead calculation: detailed conditions are displayed, 20% overhead is applied on raw materials

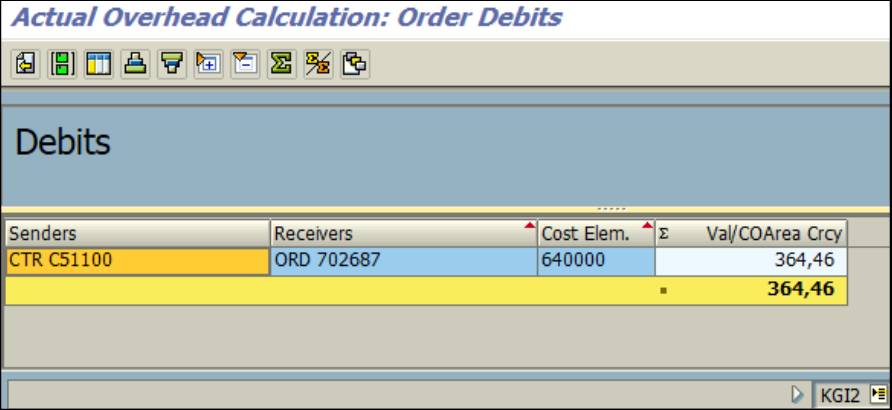

Figure 5.3 KGI2 – Overhead calculation: overhead is applied on the order, cost center is credited

6. Posting the Finished Product Goods Receipt on the CO Production Order

Figure 6.1 MB31 – Goods Receipt for Order: Movement Type 101, Order Number, Plant, Storage Location are entered.

Figure 6.2 MB31 – Goods Receipt for Order: Quantity and Batch are entered.

Figure 6.3 MB31 – Material Document for Goods Receipt is posted.

Figure 6.4 MB03 – Material Document for Goods Receipt is displayed

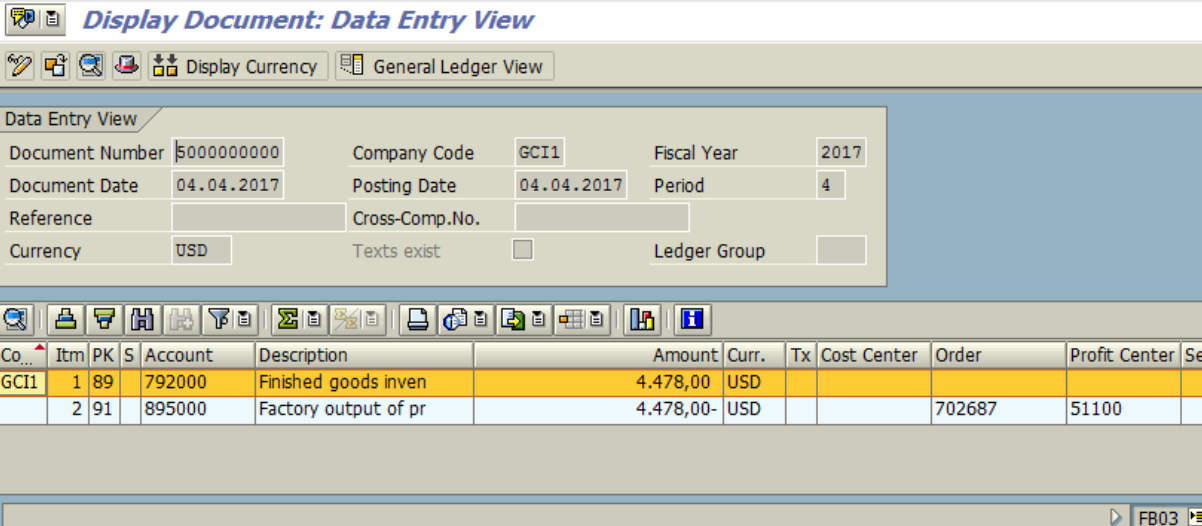

Figure 6.5 FB03 – Financial Accounting Document for Goods Receipt is displayed.

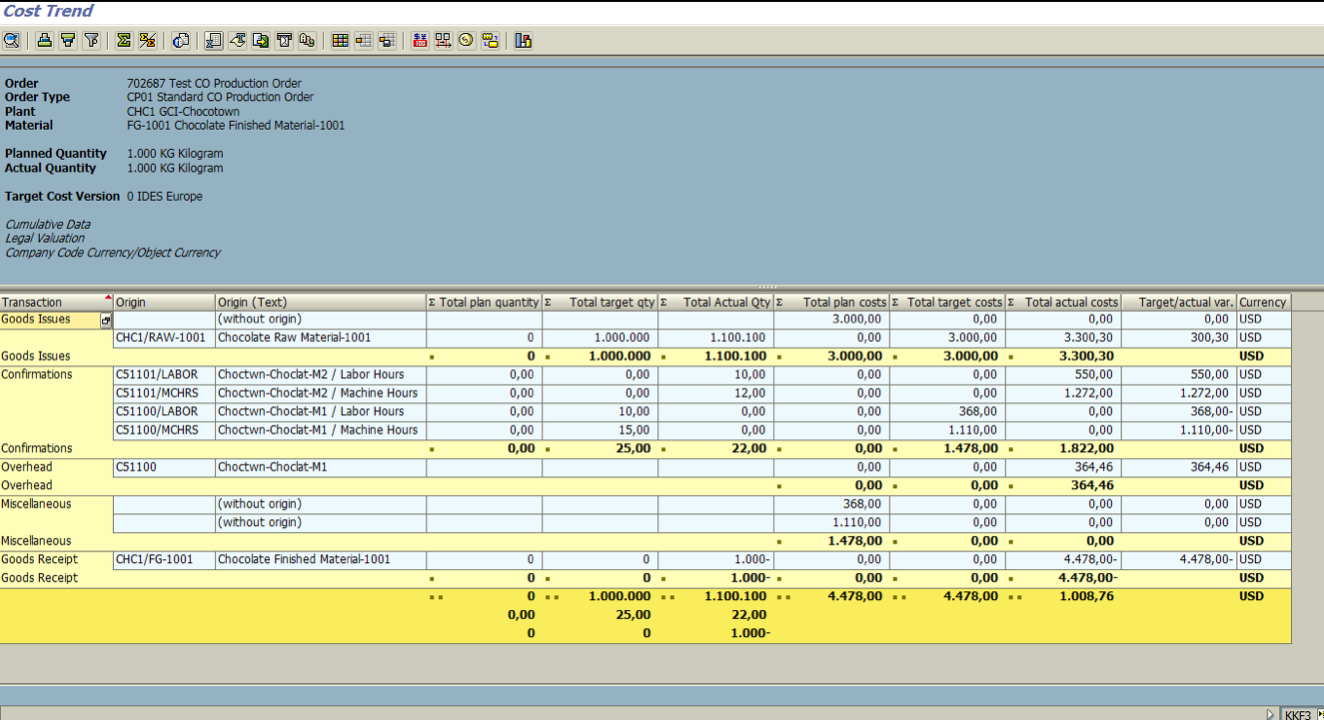

Figure 6.6 KKF3 – CO Production Order Cost Analysis screen is displayed (after all postings, but before settlement).

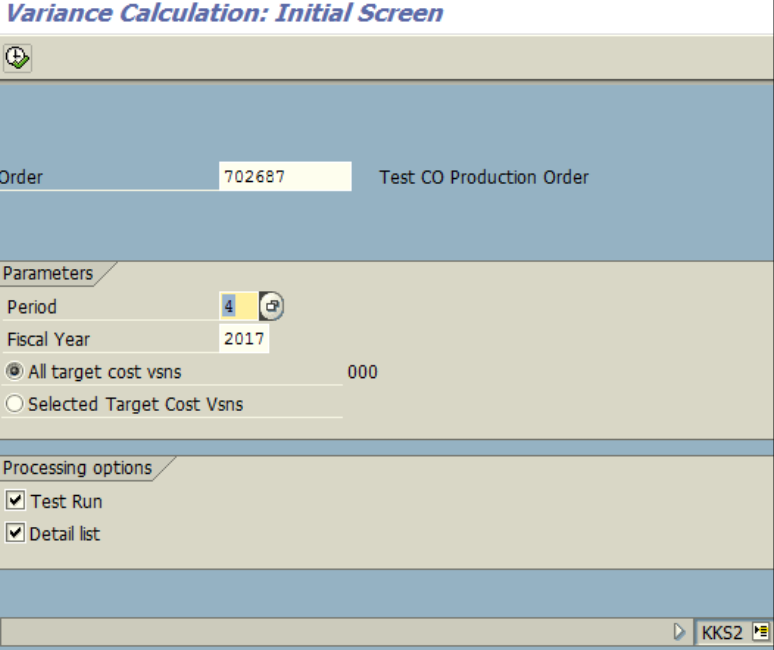

7. Calculating Variances on the CO Production Order

Figure 7.1 KKS2 – Variance calculation for order. Order, Year, Period are entered.

Figure 7.2 KKS2 – Variance calculation for order – variance by cost element is displayed.

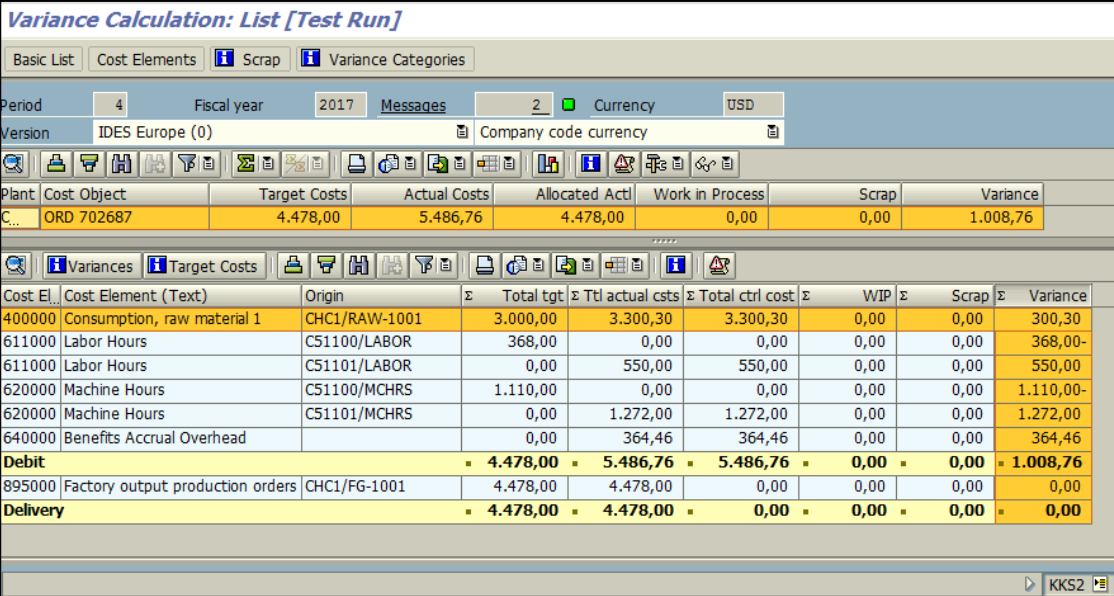

8. Settling the CO Production Order to CO-PA

Figure 8.1 KO88 – Settlement for order. Order, Year, Period are entered

Figure 8.2 KO88 – Settlement for order, with accounting documents displayed.

Figure 8.3 KO88 – Settlement for order. Costs settled to material in full